Top Benefits of a Standing Seam Metal Roof

Considering a standing seam metal roof for your home? Known for their durability, energy efficiency, and modern design, these roofs are becoming a popular choice. This article will delve into the different panel types, costs, installation steps, and more, to help you make an informed decision.

Key Takeaways

-

Standing seam metal roofs provide durability and longevity with watertight connections and concealed fasteners, reducing the risk of leaks and maintenance needs.

-

There are three primary types of standing seam panels: Snap-Lock Panels for easy installation, Mechanical Lock Panels for superior watertightness in extreme weather, and Nail Flange Panels for cost-effective projects.

-

Professional installation is recommended for standing seam metal roofs to ensure compliance with manufacturer guidelines and achieve a high-quality, durable, and energy-efficient finish.

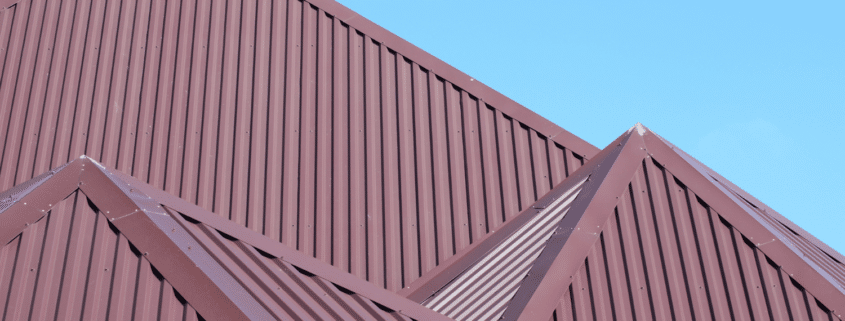

What is a Standing Seam Metal Roof?

A standing seam metal roof, a variant of classic metal roofing systems, boasts the following features of a standing seam roof system:

-

Standing seam metal panels that run vertically from the eave to the ridge of the roof

-

Raised seams that connect the adjoining metal panels, ensuring watertightness and robust structural integrity

-

Interlocked seams that can be designed diversely

-

Concealed fasteners hidden beneath the roof’s surface, providing a clean and modern look while also minimizing maintenance needs

Durability and longevity are key attributes of standing seam metal roofs. The roll-formed metal panels often come with vertical legs or ribs at each end, aiding the installation. Because there are no exposed fasteners, the chances of leaks are significantly reduced, and the fasteners themselves are protected from UV radiation, moisture, and general wear and tear over time. These attributes make standing seam roofing systems, particularly standing seam metal roofing, an excellent choice for homeowners looking for a long-lasting roofing solution.

Types of Standing Seam Metal Roofing Panels

Standing seam metal roofing panels come in various types, each offering unique installation methods and benefits. The three primary types are Snap-Lock Panels, Mechanical Lock Panels, and Nail Flange Panels. Comprehending the differences among these types can guide you to the optimal choice for your unique requirements and tastes.

Snap-Lock Panels

Snap-Lock Panels are known for their ease of installation and cost-effectiveness. These panels feature a unique snap lock system design with male and female leg components that snap together without requiring hand or mechanical seaming, making the installation process straightforward and reducing labor costs.

Homeowners seeking an economical and efficient roofing solution would find this panel type ideal.

Mechanical Lock Panels

Mechanical Lock Panels are designed for superior watertightness and are ideal for areas with extreme weather conditions. These panels are engaged using a motorized seaming machine that bends the panel legs together, forming a strong, weather-tight seal.

Mechanical seams are available in two versions – single lock 90-degree seams and double lock 180-degree seams, each exhibiting high durability.

Nail Flange Panels

Nail Flange Panels, also known as exposed fastener panels, offer a cost-effective installation method by fastening directly to the roof deck through a pre-punched fastening flange. While this method is economical, it does limit the panels’ expansion capabilities.

For simpler roofing projects driven by cost considerations, these panels are an ideal choice.

Cost Factors for Standing Seam Metal Roofs

Numerous factors, such as the type of material, labor costs, and extra expenses, shape the cost of a standing seam metal roof. Understanding these factors can help you budget for your roofing project more effectively.

Material Costs

The type of metal used determines the material costs for standing seam metal roofing. Here are the different options and their price points:

-

Steel: the most budget-friendly option

-

Copper: the most expensive due to its premium quality

-

Painted aluminum: comes with varying price points

-

Zinc: also comes with varying price points

It is essential to choose a material that fits both your budget and aesthetic preferences.

Labor Costs

The overall project cost can be significantly influenced by:

-

Labor costs

-

Geographic location

-

Experience level of the contractors

-

Complexity of the roof design

Symmetrical standing seam systems can provide labor and material savings by reducing scrap and allowing standing seam panels reuse.

Additional Costs

Removal of the old roof, repairs to the existing roof deck, and the installation of underlayment and insulation can incur additional costs. These factors can add to the roofing materials costs but are essential for the durability and energy efficiency of the new roof.

Installation Process of Standing Seam Metal Roofs

Precision and expertise are required for the installation of standing seam metal roofs. The installation process includes the following steps:

-

Securing the drip edge

-

Measuring and cutting the panels

-

Installing closure strips

-

Applying roofing sealant

This meticulous process ensures that the roof is both durable and watertight.

Professional Installation

For standing seam metal roofs, professional installation is strongly advised. Experienced professionals can ensure that the installation adheres to manufacturer guidelines, safety measures, and warranty requirements. They also have the expertise to handle the complexities of metal roof installation, ensuring a high-quality finish.

DIY Considerations

Despite appearing cost-effective, DIY installation is generally discouraged due to the associated risks. Improper installation can void warranties, lead to weather damage, and negatively impact the home’s curb appeal and resale value.

It’s best to leave this task to the professionals.

Energy Efficiency and Longevity

Energy efficiency and longevity distinguish standing seam metal roofs as a standout choice. These roofs can last between 50 to 75 years with proper maintenance and offer significant energy savings due to their reflective properties.

Reflective Properties

With high reflectivity, standing seam metal roofs can bounce back up to 70% of the sun’s energy. This reduces heat absorption and helps lower energy costs, making them an energy-efficient choice for homeowners.

Durability

With proper maintenance, standing seam metal roofs can last up to 75 years. Regular maintenance is key to ensuring their longevity. They are designed to withstand extreme weather conditions, including high winds and heavy snow loads, and come with warranties that often range from 30 to 50 years.

Design and Aesthetic Appeal

A broad spectrum of design and aesthetic options are available with standing seam metal roofs. They are available in various colors and profiles, allowing homeowners to customize their roof to match their home’s style and improve curb appeal.

Color Options

Standing seam metal roofs offer diverse color options, ranging from traditional neutral tones to vibrant shades. Homeowners can choose colors that blend seamlessly with their home’s exterior or opt for bold choices to make a statement. Custom colors are also available, although they may add to the overall cost.

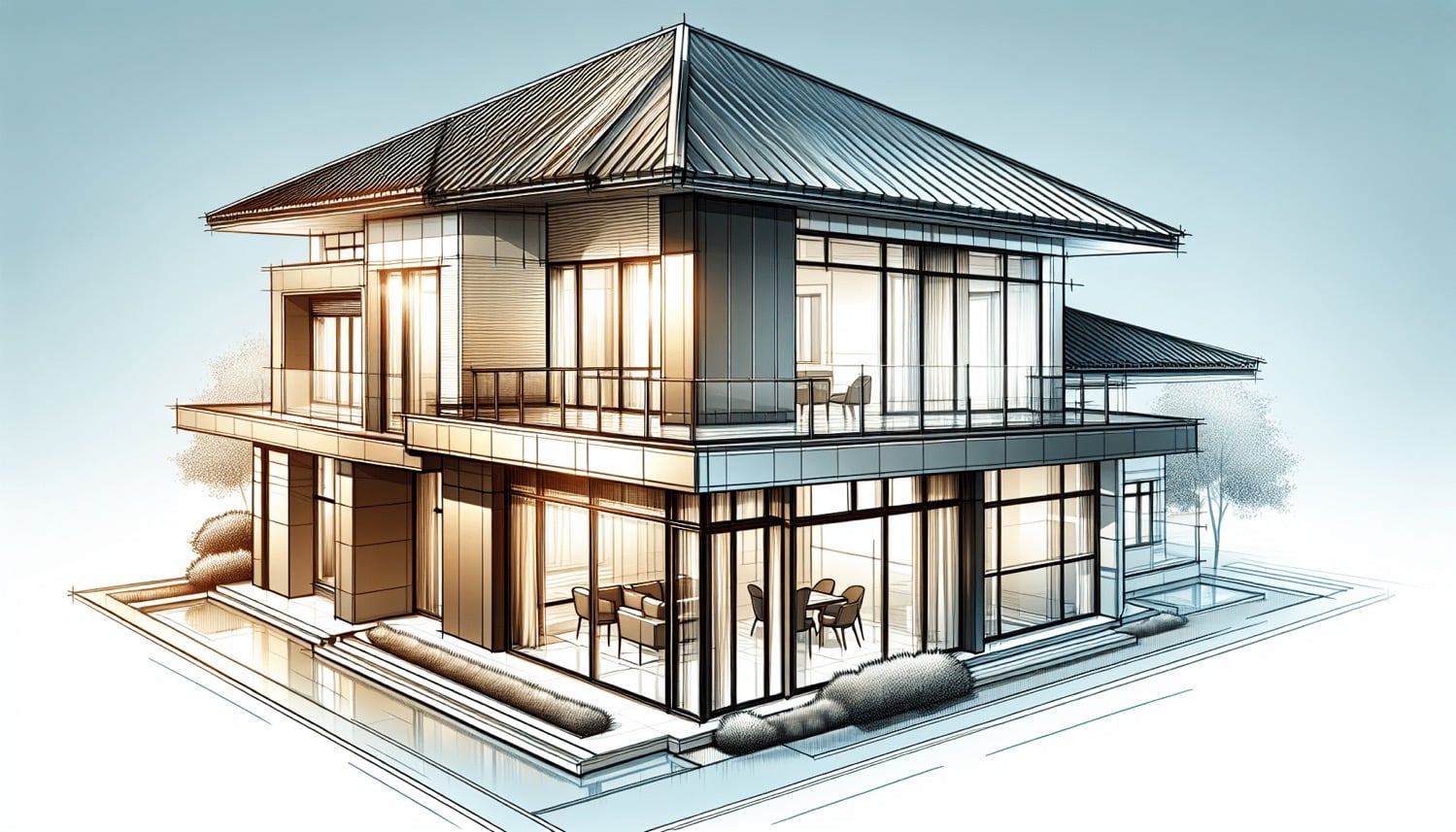

Modern Look

Clean, straight lines and concealed fasteners accentuate the modern look of standing seam metal roofs. This sleek design significantly boosts a home’s curb appeal and complements contemporary architectural styles.

Pros and Cons of Standing Seam Metal Roofs

While standing seam metal roofs boast numerous advantages like durability, energy efficiency, and low maintenance, they also present some drawbacks such as higher initial costs and the requirement for skilled installation.

Advantages

Exceptional durability, energy efficiency, and a long lifespan are among the advantages of standing seam metal roofs. These roofs are low-maintenance and provide significant cost savings over time, making them a wise investment for homeowners.

Disadvantages

Higher upfront costs and the need for skilled installation are the primary disadvantages of standing seam metal roofs. Additionally, they can produce noticeable noise during rain and may experience oil canning, a wavy appearance that can affect their aesthetics.

Maintenance Tips for Standing Seam Metal Roofs

To maintain standing seam metal roofs in optimal condition, regular maintenance is vital. This includes performing annual inspections, cleaning the roof surface, and addressing any issues promptly.

Regular Inspections

Potential issues can be identified before escalating into serious problems through regular inspections. It’s recommended to have professional inspections performed at least once every two years to ensure the roof’s integrity,.

Cleaning and Care

Cleaning and care tasks include debris removal from the roof surface, gutter and downspout maintenance, and trimming of overhanging branches. These steps help prevent scratches, stains, and water damage, ensuring the roof’s longevity.

How to Choose the Right Contractor for Installation

A successful metal roof installation hinges on choosing the right contractor. Look for contractors with proper credentials, insurance coverage, and positive reviews to ensure high-quality workmanship.

Checking Credentials

Ensure the contractor holds a valid license and has adequate insurance coverage. Proper insurance coverage is crucial to protect against any accidents or damages during the roofing work.

Reading Reviews

Insights into a contractor’s reliability and workmanship can be gleaned from reading reviews and testimonials. Look for positive reviews and high ratings from previous clients to ensure you choose a reputable contractor.

Summary

Standing seam metal roofs offer numerous benefits, including durability, energy efficiency, and aesthetic appeal. While they come with higher initial costs and require skilled installation, the long-term advantages make them a worthwhile investment. By understanding the different types of panels, cost factors, and maintenance tips, homeowners can make informed decisions about their roofing projects.

Frequently Asked Questions

What are the main types of standing seam metal roofing panels?

The main types of standing seam metal roofing panels are Snap-Lock Panels, Mechanical Lock Panels, and Nail Flange Panels. Each type offers unique features and benefits for different roofing needs.

How long can a standing seam metal roof last?

A standing seam metal roof can last between 50 to 75 years with proper maintenance, making it a durable roofing option.

What factors influence the cost of a standing seam metal roof?

The cost of a standing seam metal roof is influenced by factors such as material type, labor costs, old roof removal, and underlayment expenses. These are the main components that impact the overall cost.

Is DIY installation recommended for standing seam metal roofs?

It is not recommended to do a DIY installation for standing seam metal roofs due to potential risks including voided warranties and weather damage.

Why should I choose a standing seam metal roof over traditional materials like asphalt shingles?

You should choose a standing seam metal roof over traditional materials like asphalt shingles because it offers superior durability, energy efficiency, and a longer lifespan.

Residential Roofing

Residential Roofing Storm Damage

Storm Damage Multi-Family Homes

Multi-Family Homes