Everything You Need to Know About Standing Seam Metal Roofs: Your Comprehensive Guide

Choosing the right roof means weighing up options like standing seam metal roofs. This streamlined guide delivers everything you need to know about standing seam metal roofs, diving into their durability, design, and why they might be the cost-effective choice for your building. Expect no-nonsense explanations of installation and maintenance, and straightforward cost analysis, to help you confidently decide on your roofing investment.

Key Takeaways

-

Standing seam metal roofs offer distinct advantages through their concealed fastener system, enhancing both aesthetic appeal and weather resistance, with various materials like steel, aluminum, copper, and zinc available to suit different climates and preferences.

-

Professional installation of standing seam metal roofs is essential due to their complexity, and involves on-site fabrication and customization by skilled contractors, ensuring a precise fit and long-term durability.

-

The overall value of a standing seam metal roof is reflected in its long lifespan, energy efficiency, minimal maintenance requirements, and potential for increasing property resale value.

The Essence of Standing Seam Metal Roofing

The distinctive design of standing seam metal roofing is characterized by typical panel widths ranging from 12 to 18 inches, with 16 inches being the most prevalent. This design choice is based on performance requirements, profile compatibility, and aesthetic preferences. What sets standing seam apart from other roofing systems is its concealed fastener system, which provides a sleek and modern look, enhancing the overall aesthetic of any structure it crowns.

Raised vertical seams and a flat area between them are integral to this unique design. These components not only contribute to the appealing aesthetic but also enhance the roof’s durability and guard against weather infiltration. The raised seams create channels that prevent water from pooling on the roof surface, directing it away and guarding against potential leaks. Meanwhile, the concealed fasteners provide additional protection against harsh weather conditions.

Understanding the Anatomy of a Standing Seam Panel

Examining the anatomy of a standing seam panel unveils its intricate design and functionality. The snap lock panels feature raised interlocking seams that enhance weather resistance and prevent water penetration. The main locking systems of these panels include snap-lock, with male and female leg components that snap together, and mechanical lock, with seams that are either single or double locked.

The panel’s profile type, determined by its shape and seaming methods, significantly affects the functionality of these locking systems and overall performance of the standing seam roof.

The Significance of Concealed Fasteners

The durability and aesthetic appeal of standing seam roofs are significantly influenced by concealed fasteners. Unlike exposed fastener systems, concealed fasteners are not exposed to direct environmental conditions, reducing the risk of damage. These fasteners are hidden beneath the metal panels, providing superior defense against weather infiltration.

The concealment of fasteners offers several benefits:

-

Reinforces the roof’s structural integrity

-

Fosters a sleek roof surface by masking fasteners

-

Creates uninterrupted lines that contribute to the modern aesthetic of a standing seam roof system.

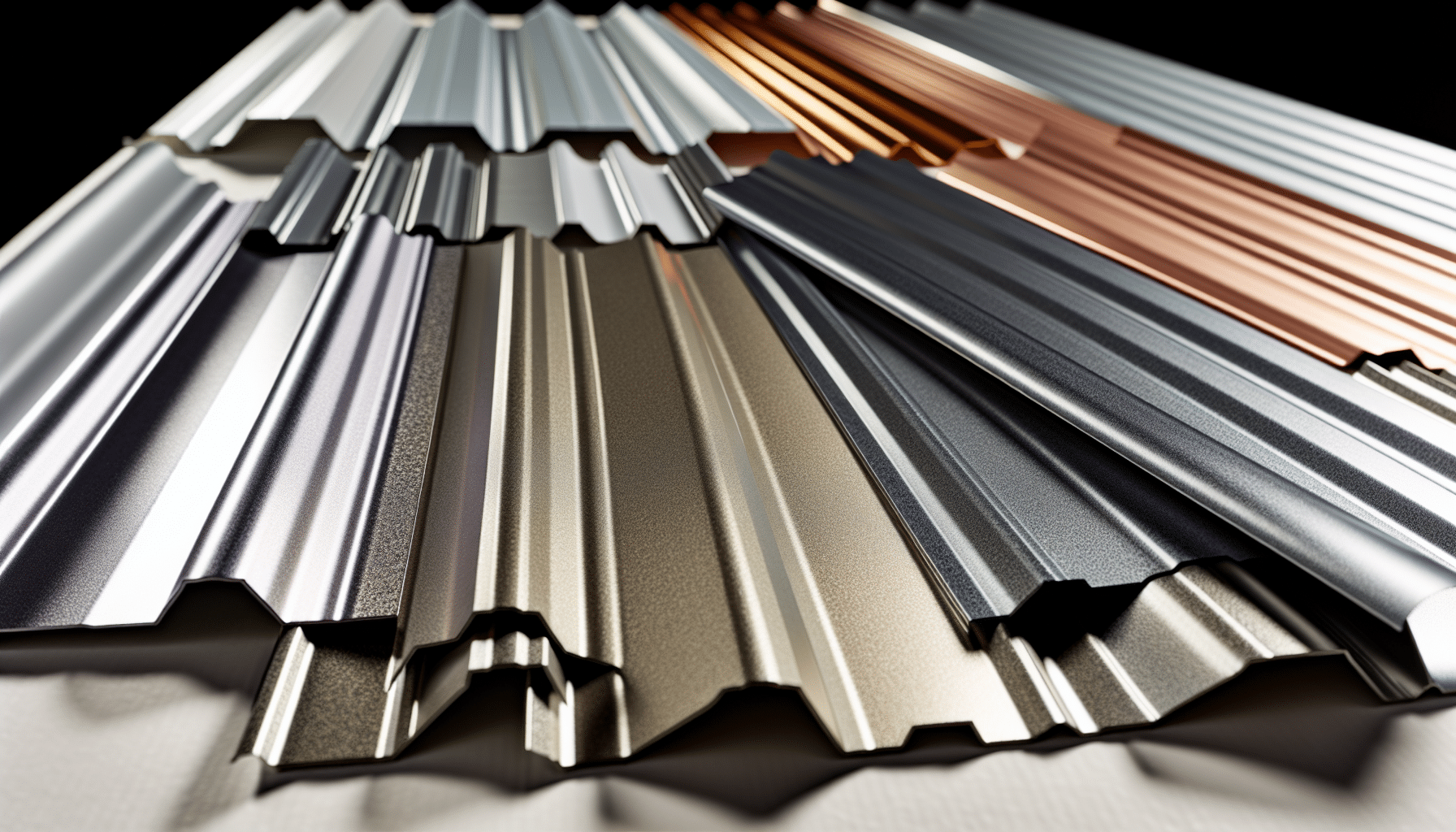

Materials and Options: Crafting Your Standing Seam Roof

A variety of materials are available for crafting your standing seam roof. Some options include:

-

Galvanized steel: provides a traditional metallic look

-

Aluminum: known for its corrosion resistance

-

Copper: offers recyclability and an evolving appearance

-

Zinc: capable of self-healing scratches

The choice of material can significantly influence the visual appeal and durability of your roof.

Steel, on the other hand, offers robustness thanks to its commonly ranging gauges from 22 to 26. The cost considerations for standing seam roofing materials range from budget-friendly to premium options. Galvanized steel and aluminum tend to be more affordable, while copper and zinc are considered higher-end choices. Your budget, coupled with your aesthetic preferences and performance needs, will ultimately determine the ideal material for your standing seam roof.

Selecting the Right Material for Your Climate

Your location’s climate is an important consideration when choosing the appropriate material for your standing seam roof. Here are some recommendations based on different climates:

-

In hail-prone areas, steel roofing is favored due to its resistance to denting.

-

For areas with dramatic weather shifts, zinc is advantageous because it can manage thermal expansion effectively.

-

In coastal climates, aluminum roofing is recommended to prevent corrosion from salt spray.

By considering environmental conditions, you can ensure the optimal performance and longevity of your standing seam metal roof.

Color Choices and Finishes

In addition to material selection, color choices and finishes provide further customization opportunities for your standing seam roof. With over 110 unique colors and finishes available for steel panels, you can truly make your roof your own. Kynar 500 resin finishes can protect metal panels from the elements and prevent color fading, with a warranty that typically covers 30 years. Opting for specialized paint finishes can affect the overall cost of a standing seam metal roof.

However, the longevity of these paint systems, maintained through periodic cleaning, upholds the strength of the resin and coating. This ensures a vibrant color retention that can significantly enhance your property’s curb appeal.

Installation Insights: What Sets Standing Seam Apart

Installing a standing seam metal roof entails a distinctive process. It includes:

-

Removing old roofing materials

-

Inspecting and replacing roof decking as necessary

-

Preparing the decking

-

Installing lock strips, drip edges, and concealment of fasteners with metal panels and Z-bar flashing

-

Conducting pre-installation checks, such as ensuring a level roof deck and employing methods to alleviate oil canning

This meticulous process sets standing seam apart in terms of installation complexity and quality of results.

The potential for on-site fabrication and customization makes standing seam truly distinctive. This allows contractors to:

-

Create panels that match the exact dimensions and angles of a specific roof structure, leading to a more precise and better-fitting installation.

-

Engage the panels through snap-lock profiles or mechanical seaming, thanks to the expertise of companies like Rapid Roofing.

-

Enable efficient installation, catering to the roof design’s complexity and features like peaks and dormers that necessitate more involved labor and precision.

On-Site Fabrication and Customization

Metal panels can be fabricated on-site, enabling contractors to tailor the panels to each roof’s unique characteristics and accommodate complex features like varied angles, hips, and valleys. The use of single-pass and bi-directional seaming machines in the installation process further enhances efficiency by operating in both directions along the roof.

Such customization and precision, achievable only through skilled contractors with experience in on-site roll forming, ensure a roof installation that fits like a glove and stands the test of time.

Professional Expertise Required

Installing a standing seam roof requires the expertise of skilled contractors familiar with specialized tools and techniques due to its complexity. Some essential tools and techniques for installing a standing seam roof include:

-

Seamers, either mechanical or hand-operated, for installing concealed fastener systems

-

Securing with clips and screws

-

Ensuring proper flashing around roof penetrations

-

Securing the panels with specialized clips or fasteners

Such precision is required to ensure a proper installation and to achieve a durable and long-lasting standing seam roof.

Post-installation inspections by contractors are also crucial to ensure all seams are perfectly sealed and the roof is defect-free.

Advantages of Standing Seam Metal Roofs

A myriad of advantages are offered by standing seam metal roofs. Here are some of the key benefits:

-

Known as a ‘Lifetime Roof,’ they are capable of lasting 40-70 years, or even over a century for materials like copper.

-

Their energy efficiency sets them apart, utilizing cool pigments in their finish to reflect solar heat, improving thermal emittance, and reducing energy costs by 7%-15%.

-

Their maintenance needs are minimal, often requiring no more than occasional inspections to maintain their condition.

In addition to their durability and energy efficiency, standing seam metal roofs offer several benefits:

-

Highly resistant to leaks, weather, and fire, thanks to their design features like raised seams and concealed fasteners

-

Wide range of color options, allowing homeowners to customize the look to match their home’s style

-

Installing a standing seam metal roof has been shown to increase the resale value of a home, with potential cost recoupment of 85%-95%.

Enhanced Durability and Wind Resistance

Exceptional resistance to wind, rain, snow, and hail damage is provided by the vertical seams and raised structure of standing seam roofs. Their design accommodates thermal movement without damaging the structure, which is essential for maintaining their long-term integrity. Stainless steel roofing options offer superior strength, capable of withstanding particularly harsh climatic conditions. Lock strips secure the metal panels to the roof’s edges, preventing the panels from flapping in strong winds.

The durability of metal roofing materials like Galvalume® coated steel is recognized by experts, with lifespans matching the full-service life of buildings.

Energy Efficiency and Eco-Friendliness

Energy efficiency and eco-friendliness characterize standing seam metal roofs. They incorporate highly reflective surfaces that reduce heat absorption, helping buildings stay cooler and decreasing the need for air conditioning. The metals used in roofing have a high thermal emittance, facilitating the release of any absorbed heat, further supporting energy efficiency.

Moreover, materials commonly used in standing seam roofs, such as steel and aluminum, are often made from recycled content and are fully recyclable, contributing to eco-friendly building practices.

Maintenance and Care for Longevity

Maintaining the longevity of your standing seam roof necessitates proper care. Regular check-ups every one to two years by professionals can identify any potential issues. Structural maintenance involves checking and fixing fasteners, rivets, screws, and loose or damaged flashing materials. Gutters and drains should be cleaned out at least annually to prevent clogging and standing water, which can lead to premature corrosion. The roof surface should also be cleaned to remove dirt, mildew, stains, and other elements that can shorten its lifespan and affect its appearance.

In terms of aesthetic concerns, the following issues should be remedied quickly to preserve the roof’s look and integrity:

-

Scratches

-

Scuffs

-

Chipping

-

Flaking

-

Excessive chalking/fading

A touch-up paint pen that matches the color of the roof can be used to cover minor surface scratches. For tougher stains like oil, paint, or grease on PVDF-coated roofs, solvents may be used but only in the affected areas.

Regular removal of debris from valleys and dead spots on the roof is essential to prevent paint scratches and staining.

Regular Check-ups and Cleaning

Comprehensive care for your standing seam roof, including safety checks and cleaning, is offered by regular professional maintenance services. Maintenance frequency is influenced by the climate, with milder climates requiring at least yearly check-ups, whereas severe climates may necessitate more frequent maintenance.

Cleaning of the metal roof can be done using mild laundry detergent, car washing soap, mild dish soap, or commercial detergents. For tougher stains like oil, paint, or grease on PVDF-coated roofs, solvents such as rubbing alcohol, mineral spirits, or VM&P Naphtha may be used but only in the affected areas.

Managing Aesthetic Concerns

Maintaining the longevity and appearance of your standing seam roof involves managing aesthetic concerns as a vital aspect. A touch-up paint pen that matches the color of the roof can be used to cover minor surface scratches. For more severe cosmetic issues like rust stains, mild cleaners and diluted acid solutions may be applied with caution and must be rinsed promptly to prevent damage to the metal.

Regular removal of debris from valleys and dead spots on the roof is essential to prevent paint scratches and staining. It’s important to test the chosen cleaning method on an inconspicuous part of the roof first to ensure it doesn’t cause unintended damage when applied broadly.

Retrofitting with Standing Seam Systems

Compared to total replacement, retrofitting with standing seam systems presents benefits and compatibility with existing structures. Companies like McElroy Metal offer a variety of retrofit systems, including solutions designed for metal-over-metal and metal-over-shingle applications. These systems are tailored to the existing roof’s support structure, ensuring a long-lasting solution that also enhances the building’s curb appeal.

Retrofit systems can be more economical than a complete roof replacement, particularly for roofs that frequently require maintenance due to conventional roofing materials.

Compatibility with Existing Structures

Known for their durability, standing seam metal roofs have the following features:

-

Can be installed on a wide range of roof slopes

-

Can withstand wind speeds up to 140 mph, heavy snow, and torrential rain

-

On-site roll forming allows for the creation of very long standing seam panels that are customized to the project’s requirements

-

Compatible with existing structures that may have large or unconventional dimensions

Benefits of Retrofitting vs. Total Replacement

For roofs that need frequent maintenance due to conventional roofing materials, retrofitting with systems like the 238T Metal-Over-Metal and 138T Shingle Recover can be more economical than a complete roof replacement. Retrofitting can not only extend the life of an existing roof but also enhance energy efficiency and the aesthetic appeal of the building. Classic metal roofing systems designed for retrofitting require minimal maintenance, which translates into lower operational costs and fewer long-term issues.

It’s noteworthy that retrofitting with a metal roofing system can increase property value by improving both curb appeal and long-term roof performance.

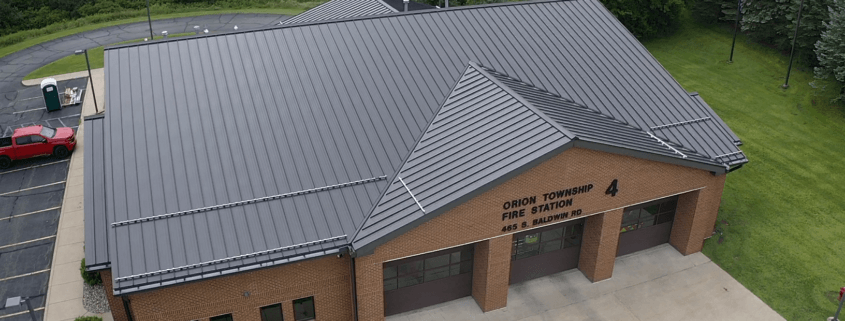

Real-World Applications: Case Studies and Testimonials

Real-world results are the most compelling evidence. Both residential and commercial clients have experienced notable improvements in their properties thanks to standing seam metal roofs. Some of the benefits reported by homeowners and commercial property owners include:

-

Enhanced resale value

-

Improved curb appeal

-

Increased energy efficiency

-

Long-lasting durability

-

Low maintenance requirements

Investing in high-quality metal roofing panels, particularly when choosing attractive colors, can truly transform the look and value of a property.

On the commercial side, clients have commended the aesthetic enhancements and functional advantages of metal roofing, highlighting the installation precision and effective waterproofing and sealing techniques.

Residential Success Stories

Following the installation of standing seam metal roofs, residential clients have noted significant improvements in their properties. Testimonials from homeowners emphasize the increase in their home’s resale value and enhanced curb appeal.

Moreover, the wide range of colors available for standing seam metal roofs allows homeowners to customize the look to match their home’s style, further enhancing its visual appeal.

Commercial Projects Showcase

Standing seam metal roofs have also bestowed benefits upon commercial clients. Some of these benefits include:

-

Aesthetic enhancements

-

Improved waterproofing and sealing techniques

-

Attractive appearance

-

Minimal maintenance

-

Boosting inquiries and business referrals

One business owner reported a favorable outcome after selecting metal roofing to represent their insurance company’s quality.

Navigating Cost and Investment

Comprehending the cost and investment involved in a standing seam metal roof is vital. Standing seam metal roofs cost between $10 to $35 per square foot, which equals $1,000 to $3,500 per roofing square. Labor costs for installation typically range from $3,400 to $10,000, equating to $2 to $6 per square foot.

The average installation cost for a 2,000-square-foot steel or aluminum standing seam roof ranges from $20,000 to $34,000.

Understanding Price Variables

The cost of a standing seam metal roof is influenced by several factors, including:

-

The type of material used (aluminum roofing materials may increase the cost by 20% to 30% over steel roofing)

-

Labor costs, which can vary depending on the geographic location and are higher during peak seasons

-

The type of fastener system chosen (a concealed fastener system typically incurs higher material and labor costs, but these can be justified by the roof’s performance and longevity)

The cost for removal and disposal of an old roof, if not included in the new roof’s price, can range from $1 to $5 per square foot.

Return on Investment Analysis

Despite its initially higher cost compared to other roofing options, a standing seam metal roof offers a significant return on investment over time. These roofs have markedly longer lifespans, with warranties covering at least 30 years compared to asphalt’s average lifespan of 15 to 20 years, which can greatly reduce the frequency of roof replacements. Over the course of 30 years, the ownership costs of a metal roof are estimated to be about 50% less than what one would incur from replacing an asphalt shingle roof twice, when factoring in maintenance and insurance costs.

Furthermore, a standing seam metal roof can contribute to property value with a return on investment of approximately 48.9%, according to Remodeling magazine’s 2024 Cost vs. Value report.

Accessorizing Your Standing Seam Roof

The functionality and aesthetic appeal of your standing seam roof can be enhanced by accessorizing it. A range of accessories, such as solar panels, snow retention systems, and skylights, can be seamlessly integrated with standing seam metal roofs. The design of these roofs accommodates the installation of these accessories without the need for penetrating fasteners, thus preserving the weather-tightness and longevity of the roof.

Enhancing Functionality and Safety

The functionality of standing seam roofs can be enhanced by specific safety features and accessories. In regions with heavy snowfall, snow guards or snow retention systems are added to prevent the snow from sliding off in large sheets, thus protecting property and individuals around a building.

Additionally, swamp coolers, used for enhancing indoor comfort, can be successfully installed on standing seam metal roofs, contributing to a cooler interior space without compromising roof integrity.

Solar Integration without Compromising Integrity

Without compromising their integrity, solar panels can be securely mounted on standing seam roofs. Solar panels can be attached to the seams using clamps, eliminating the need for penetrative methods such as drilling. The lightweight nature of metal roofs makes them an ideal platform for solar panels, offering a durable platform that can outlive the solar panels themselves without requiring additional support for the weight.

The mounting system on standing seam metal roofs is designed to facilitate easy swapping of solar panels when the time comes for replacement, without the need for new mounts or drilling.

Summary

In conclusion, standing seam metal roofs offer a unique blend of durability, aesthetic appeal, and functionality. Their distinctive design, range of material and color options, and compatibility with various structures and accessories make them a versatile choice for both residential and commercial properties. Although the initial cost could be higher than other roofing options, their long-term benefits, such as energy efficiency, minimal maintenance, and increased property value, make them a wise investment. By considering your specific needs and the local climate, you can select the ideal standing seam metal roof that will serve you well for many years to come.

Frequently Asked Questions

What are the disadvantages of a standing seam roof?

Standing seam metal roofs have four main disadvantages, including potential for oil canning, higher initial cost, difficulty in repairing, and potential for installation issues. These factors should be considered before choosing this type of roof for your building.

Is standing seam metal roof worth it?

Yes, a standing seam metal roof is worth it, as it has a return on investment of 48.9% according to Remodeling magazine’s 2024 Cost vs. Value report. Keep this in mind when planning for roof replacement.

What is the life expectancy of a standing seam metal roof?

With proper installation and ventilation, a standing seam metal roof can last 30-50 years.

Is standing seam metal roof hard to install?

Installing a standing seam metal roof is more challenging than corrugated metal due to the precision required in attaching the panels and trim to prevent leaks. The cost of labor for standing seam metal roofing installation ranges from $5 to $10 per square foot.

What makes standing seam metal roofs unique?

Standing seam metal roofs are unique due to their raised interlocking seams and concealed fasteners, which enhance durability and weather resistance while providing a modern aesthetic.