Top Benefits and Drawbacks of a Modified Bitumen Roof

A modified bitumen roof is a popular choice for commercial buildings with flat or low-slope roofs. Made from asphalt blended with rubber or plastic polymers, it offers durability and flexibility, with excellent weather resistance. This article covers the key benefits and drawbacks of modified bitumen roofing systems, helping you decide if it’s the right option for your building.

Key Takeaways

-

Modified bitumen roofing systems are durable and flexible, making them ideal for flat and low-slope commercial roofs due to their strong weather resistance and longevity.

-

These roofing materials come in two primary types, APP and SBS, each offering unique characteristics such as UV resistance and flexibility, catering to various installation needs.

-

While modified bitumen roofs present advantages like superior waterproofing and energy efficiency, they also have drawbacks, including a relatively shorter lifespan and potential heat absorption issues.

Understanding Modified Bitumen Roofs

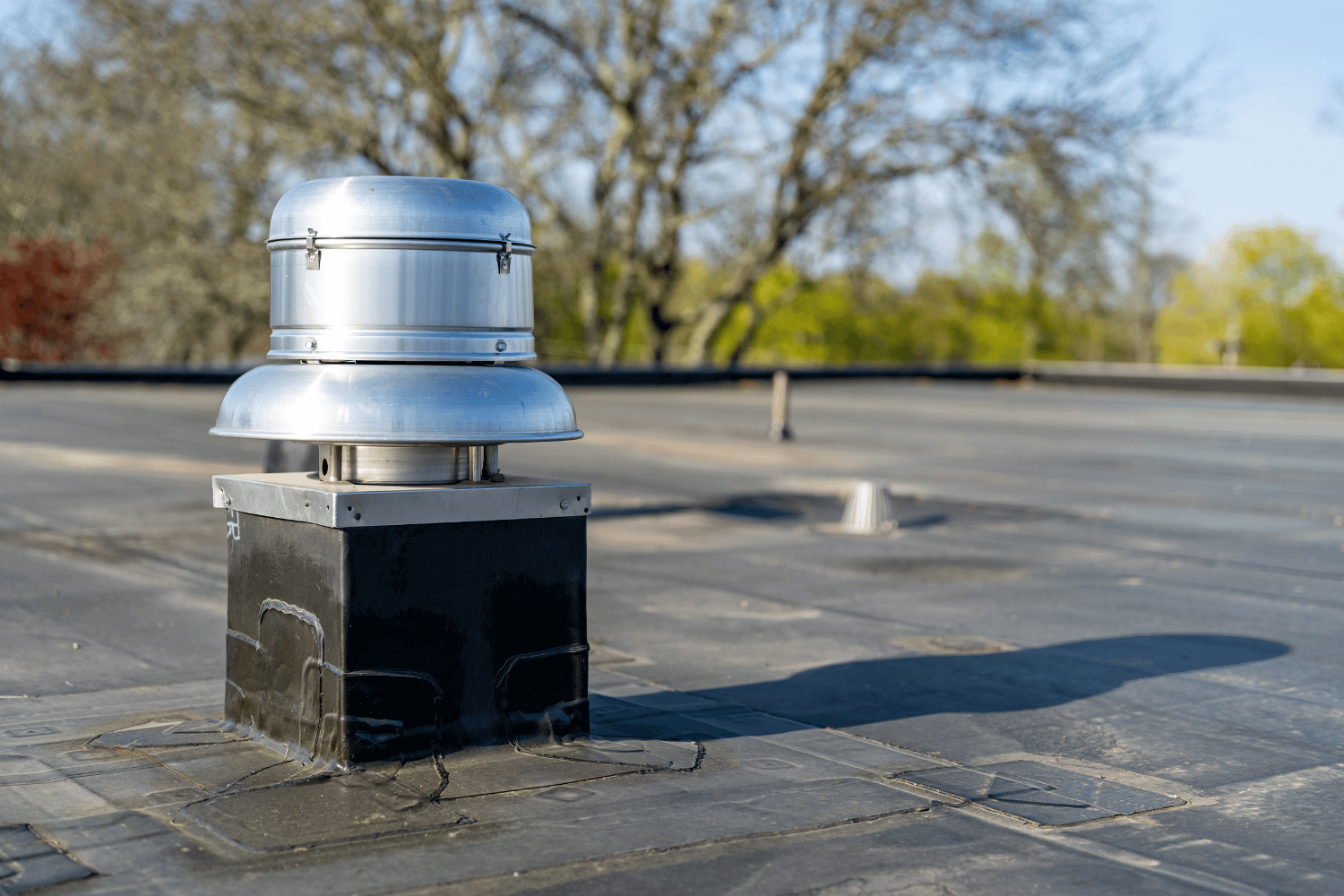

Modified bitumen roofing is a versatile solution crafted from asphalt blended with rubber or plastic polymers, creating a material that is both durable and flexible. This sophisticated roofing system utilizes asphalt membranes that are reinforced with fiberglass, adding an extra layer of strength and resilience. Its unique composition allows it to perform exceptionally well under various environmental conditions, making it a popular choice for flat and low-slope roofs commonly found in commercial buildings.

Ideal for low-slope commercial roofs, modified bitumen roofs offer robust weather protection, extending the roof’s lifespan. They are particularly effective in withstanding extreme weather, making them a reliable choice for commercial flat roofs.

Modified bitumen roofing systems exemplify advancements in mod bit roof technology, offering a modern alternative to traditional materials, including a modified bitumen membrane roof.

History and Evolution of Modified Bitumen Roofing Systems

The journey of modified bitumen roofing systems began in the mid-1960s, evolving from the traditional built-up roofing systems (BUR) that had dominated the market. After World War II, the need for advanced roofing materials became apparent, leading to the development of synthetic materials like modified bitumen. These innovations significantly transformed the roofing market, offering enhanced durability and flexibility compared to their predecessors.

By the 1970s, modified bitumen roofing had gained favor for its superior performance, surpassing built-up roofing in reliability. Its introduction marked a significant shift in commercial roofing, and over the last 50 years, it has become one of the most widely used systems.

Today, modified bitumen roofing is celebrated for its exceptional tensile strength, longevity, and relatively straightforward installation, making it one of the most dependable roofing materials and a preferred choice for flat commercial roofs.

Types of Modified Bitumen Membranes

Modified bitumen roofing can be broadly categorized into two main types: APP (Atactic Polypropylene) and SBS (Styrene-Butadiene-Styrene) membranes. Each type has distinct characteristics that cater to different roofing needs. While APP membranes are known for their UV resistance and rigidity, SBS membranes are prized for their flexibility and resilience.

Both types are structured to include multiple layers, adding strength and functionality to the roof systems roofing system.

APP (Atactic Polypropylene) Membranes

APP membranes, made from asphalt mixed with plasticized polymers, have a plastic-like appearance and increased UV protection. This composition makes them effective in removing water and resisting ultraviolet rays, thus prolonging the roof’s lifespan. The torch-down installation method, which heats the membrane to temperatures of 300 degrees or hotter, ensures a strong bond and a water-resistant seal.

While effective, this method requires stringent safety measures due to the heavy fumes produced. Proper safety equipment and procedures protect both installers and the environment.

Despite these challenges, APP membranes’ robustness and UV resistance make them popular for many commercial roofing projects.

SBS (Styrene-Butadiene-Styrene) Membranes

SBS membranes, made from a combination of asphalt and polymerized rubber, offer superior elasticity and flexibility. They can expand and contract without cracking, making them ideal for roofs experiencing temperature fluctuations and high winds. SBS modified bitumen roofing suits commercial, industrial, and low-slope institutional structures.

SBS membranes’ synthetic rubber properties provide excellent resistance to foot traffic and impacts, making them a durable choice for buildings needing a reliable and long-lasting roof system. The combination of asphalt and polymerized rubber ensures they can withstand harsh weather, offering a dependable roofing solution for various commercial applications.

Installation Methods for Modified Bitumen Roofs

Installing modified bitumen roofing typically involves rolled sheets that are 3 feet wide and up to 36 feet long. Methods include heat welding, mopping in hot asphalt, cold-process adhesive, and self-adhering membranes.

Each method has its benefits and challenges, so choosing the right technique based on the roofing project’s specific requirements is crucial.

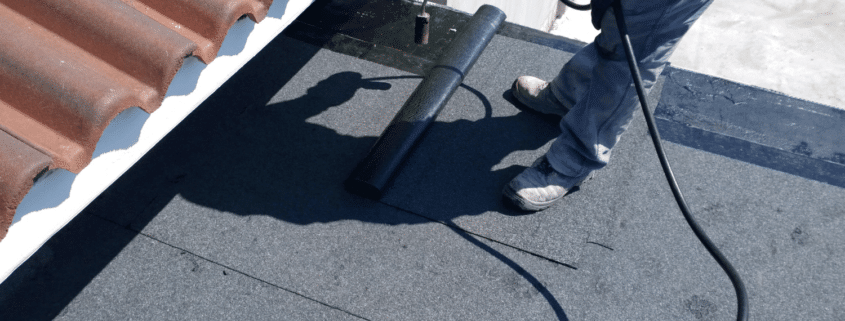

Torch-Applied Method

The torch-applied method uses a torch to heat the membrane, creating a strong bond and ensuring a water-resistant seal. It is particularly effective in enhancing leak resistance with a seamless finish that prevents water infiltration. However, the process produces heavy fumes, necessitating proper safety equipment to protect installers’ health and the environment.

While the torch-applied method offers a durable and long-lasting roofing solution, it also comes with potential hazards. Improper torch handling can lead to fire risks, and the strong odors during installation can be a nuisance. Therefore, hiring experienced professionals well-versed in safety protocols is crucial.

Cold Adhesive Application

Cold adhesive application is another popular method for modified bitumen installation of modified bitumen roofs. This technique allows for installation in cooler temperatures and offers flexibility during varying weather conditions. Using cold adhesives makes the installation process safer and more efficient, reducing heat and fire risks.

Self-Adhering Membranes

Self-adhering membranes simplify the installation process of modified bitumen roofing, making it more straightforward compared to traditional methods. These membranes significantly reduce installation time, leading to lower labor costs.

Additionally, they enhance safety by eliminating the need for open flames, making them a preferred choice for many commercial projects.

Key Benefits of Modified Bitumen Roofing Systems

Modified bitumen roofing systems offer numerous benefits, making them a preferred choice for commercial buildings. These include durability, flexibility, superior waterproofing, and energy efficiency. Properly installed modified bitumen roofs provide long-term protection and help keep energy costs low, making them a reliable and cost-effective solution.

Durability and Flexibility

Modified bitumen roofing materials are designed to withstand extreme weather, ensuring long-lasting performance. These roofs can expand and contract without cracking, enhancing their lifespan. The combination of asphalt with polymerized rubber or plastic additives provides a flexible yet durable membrane that can handle foot traffic and other impacts, making them a choice for dependable roofing materials.

Additionally, modified bitumen roofs are highly durable and require minimal maintenance, as they rarely sustain damage over time. This durability, coupled with flexibility to adapt to temperature swings, makes them a practical choice for many commercial applications.

Superior Waterproofing Protection

A standout feature of modified bitumen roofing systems is their excellent waterproofing. When installed as multi-ply systems, these roofs create a robust barrier against leaks, thanks to the lack of seams and the use of multiple layers. This multi-layered approach ensures that water cannot easily penetrate the roof, providing long-lasting protection against moisture damage.

APP membranes are known for their plastic-like properties and resistance to ultraviolet rays, contributing to their effectiveness and durability. These properties make modified bitumen roofing systems a dependable choice for buildings requiring superior waterproofing capabilities.

Energy Efficiency

Energy efficiency is another significant benefit of modified bitumen roofing systems. These roofs reflect sunlight, reducing heat absorption and lowering energy costs. Reflective coatings further enhance this effect, making modified bitumen roofs an energy-efficient option for commercial buildings.

However, dark-colored membranes can increase heat absorption, leading to higher energy costs for cooling during the summer. Despite this, the overall energy efficiency of modified bitumen roofs, especially with reflective coatings, makes them a cost-effective alternative for many commercial applications.

Drawbacks of Modified Bitumen Roofs

While modified bitumen roofs offer many advantages, they also come with certain drawbacks, including a shorter lifespan compared to other roofing materials, heat absorption issues, and installation challenges. Understanding these drawbacks is crucial for making an informed decision about whether modified bitumen roofing is the right choice for your building.

Shorter Lifespan Compared to Alternatives

The average lifespan of modified bitumen roofs typically ranges from 10-20 years, shorter compared to materials such as TPO or PVC. Excessive wear and tear can further shorten their service life, making regular condition monitoring essential. Despite their shorter lifespan, modified bitumen roofs remain cost-effective due to lower initial installation costs and reliable performance.

Addressing early warning signs of damage and performing regular maintenance can maximize the service life of modified bitumen roofs. This proactive approach helps extend the lifespan and ensures reliable protection for your building.

Heat Absorption Issues

A primary drawback of modified bitumen roofs is their tendency to absorb heat due to dark-colored membranes. This heat absorption can lead to higher interior temperatures, increasing reliance on air conditioning and raising energy costs. The dark pigmentation, while intentional for durability and UV stability, can result in significant heat transfer into the building.

Reflective coatings can be applied to the roof surface to reduce heat absorption and improve energy efficiency. Addressing heat absorption concerns allows building owners to enjoy the benefits of modified bitumen roofing while maintaining comfortable indoor temperatures.

Installation Challenges and Odor

The installation process for modified bitumen roofs can present several challenges, including harmful fumes and fire hazards, particularly with the torch-applied method. Proper safety precautions and equipment are essential for a safe installation. Additionally, the strong odor produced during installation can persist for several days, making it advisable for building occupants to relocate temporarily.

Despite these challenges, professional installation by an experienced commercial roofing contractor can help mitigate the risks and ensure successful roof installation. Choosing a certified roofing contractor with a proven track record can significantly improve overall safety and effectiveness.

Maintenance and Repair of Modified Bitumen Roofs

Regular maintenance is essential to keep modified bitumen roofs in optimal condition. Inspections should ideally occur twice a year to identify and address potential issues early. Common maintenance tasks include patching damaged areas and securing compromised sections after severe weather events. Bitumen patches effectively repair leaks and extend the roof’s lifespan.

While modified bitumen roofs require minimal upkeep, monitoring for pooling water and other signs of damage is essential. Promptly addressing these issues can prevent more significant problems and ensure reliable roof protection for your building.

Choosing the Right Contractor for Modified Bitumen Roof Installation

Selecting the right contractor for modified bitumen roof installation is crucial to ensure a successful and durable roofing system. Look for contractors with relevant licenses and certifications, such as GAF Master Elite or Certainteed 5-Star certifications, demonstrating their compliance with legal and quality requirements. Contractors who utilize advanced technology in installations can enhance accuracy and efficiency, ensuring a high-quality roofing process.

Clear communication and transparent pricing are essential qualities to seek in a contractor. This helps avoid unexpected costs and ensures you are fully informed throughout the project.

Evaluating previous work and client references can provide insights into the contractor’s reliability and quality of service, allowing you to make an informed choice for your modified bitumen roof installation.

Comparing Modified Bitumen with Other Commercial Roofing Systems

When comparing modified bitumen roofing systems with other commercial roofing options like TPO and PVC, several factors come into play. Modified bitumen roofs are multi-layered systems derived from built-up roofing, offering enhanced durability and resistance to tears and impacts. TPO roofs, on the other hand, are single-ply systems known for their high UV resistance and effectiveness in warmer climates.

While TPO roofs can last 20-30 years, modified bitumen roofs typically have a lifespan of around 20 years. However, modified bitumen systems offer better resistance to foot traffic and can handle extreme weather conditions more effectively. Understanding these differences can help you choose the roofing system that best meets your building’s specific needs and environmental conditions.

Summary

Modified bitumen roofing systems provide a reliable and cost-effective solution for commercial buildings with flat or low-slope roofs. Their durability, flexibility, superior waterproofing protection, and energy efficiency make them a preferred choice for many property owners. Despite some drawbacks, such as a shorter lifespan and heat absorption issues, the benefits often outweigh these concerns.

By choosing the right installation method and contractor, and maintaining regular upkeep, you can maximize the performance and longevity of your modified bitumen roof. With the insights provided in this guide, you are well-equipped to make an informed decision that ensures the safety and durability of your commercial property.

Frequently Asked Questions

What is modified bitumen roofing made of?

Modified bitumen roofing consists of asphalt blended with rubber or plastic polymers, and is typically reinforced with fiberglass to enhance its durability and strength. This composition ensures a reliable and long-lasting roofing solution.

How long does a modified bitumen roof typically last?

A modified bitumen roof typically lasts between 10 to 20 years. Its longevity largely depends on the quality of installation and regular maintenance practices.

What are the main benefits of modified bitumen roofing systems?

The main benefits of modified bitumen roofing systems are their durability, flexibility, superior waterproofing protection, and energy efficiency. These features ensure long-lasting performance and cost-effectiveness.

What are the common installation methods for modified bitumen roofs?

The common installation methods for modified bitumen roofs are torch-applied, cold adhesive application, and self-adhering membranes. Each method offers distinct advantages depending on specific project needs.

How can I choose the right contractor for modified bitumen roof installation?

To choose the right contractor for modified bitumen roof installation, ensure they possess relevant licenses and certifications, demonstrate clear communication, offer transparent pricing, and have positive client references. This will guide you toward a reliable and qualified professional.

Residential Roofing

Residential Roofing Storm Damage

Storm Damage Multi-Family Homes

Multi-Family Homes