Top Solutions for Standing Seam Roof Repair

Need to fix your standing seam roof? This guide covers common issues like leaks and loose panels, and offers practical standing seam roof repair tips. Learn how to keep your roof in top shape.

Key Takeaways

-

Standing seam roofs are durable and versatile, but they require regular inspections to prevent leaks caused by improper installation or weather damage.

-

Common issues include fastener failures and seam laps, which can be addressed through proactive maintenance and repairs to extend the roof’s lifespan.

-

Homeowners should weigh repair, restoration, and replacement options based on their roof’s condition, and consider hiring professionals to ensure effective repairs.

Top Solutions for Standing Seam Roof Repair

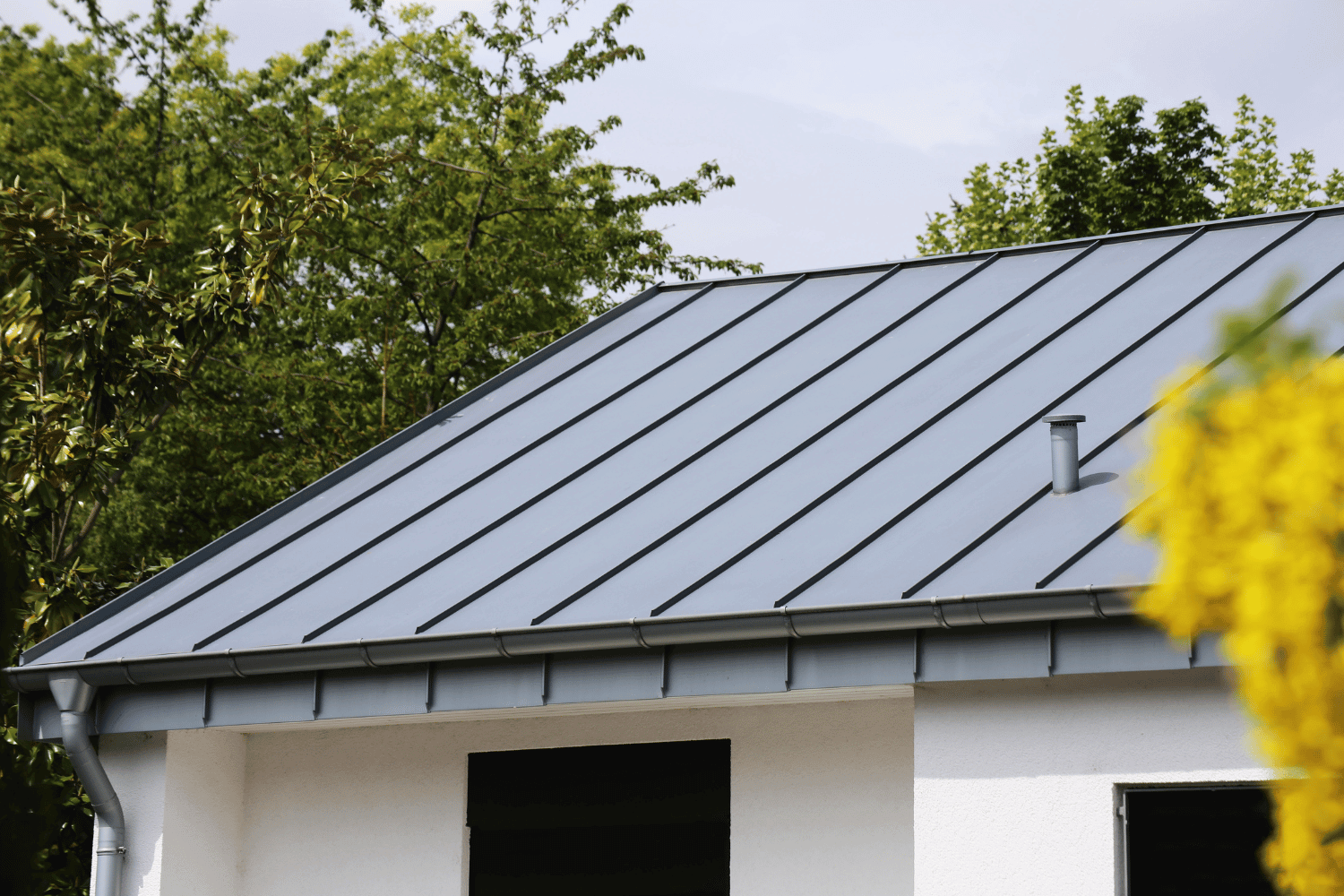

Standing seam metal roofing is increasingly favored due to its durability and modern aesthetic. These roofing systems consist of panels with vertical legs and a concealed fastener system, which makes them both robust and visually appealing. The adaptability of standing seam systems for both roofs and wall applications adds to their versatility.

However, even the most resilient roofing systems are not without their issues. Missing or poorly secured panels can compromise the performance of metal roofing, making them vulnerable to high winds and subsequent leaks. Leaks in standing seam metal roofs, often caused by improper installation and damage from extreme weather conditions, can be a significant concern. Failing to properly accommodate thermal movement in these roofs can lead to water infiltration and stress fractures in the seams.

Regular inspections are crucial to identifying potential issues before they escalate into costly repairs. These inspections can reveal problems like fastener failures and open seam laps, which are common sources of leaks. Addressing these issues promptly can save homeowners from the headache and expense of more extensive repairs down the line.

Introduction

A standing seam metal roof is a roofing system characterized by vertical seams that interlock, providing a sleek and durable finish. These roofs are not just about looks; they offer numerous benefits, such as concealed fasteners and flashing methods that enhance both durability and aesthetics. However, standing seam metal roofs come with their own set of challenges, including higher costs compared to traditional roofing materials.

Standing seam roofs are versatile and can be found in residential, agricultural, and commercial buildings. They can be installed on slopes as low as 0.5/12, making them suitable for various architectural designs. With materials like aluminum, zinc, steel, and copper, these roofs can withstand extreme conditions, including wind, snow, and hail, while providing long-lasting protection.

In this guide, we’ll explore the installation methods, benefits, disadvantages, and costs associated with standing seam metal roofs.

Identifying Common Issues in Standing Seam Metal Roofs

Standing seam metal roofing is known for its durability and modern aesthetic, making it a popular choice for many homeowners. However, its installation process is more labor-intensive than other types of roofing, potentially leading to issues if not done correctly. This roofing type consists of panels with vertical legs and a concealed fastener system, which, while advantageous, requires precise installation to ensure long-term performance.

Poorly secured panels are a common issue with standing seam metal roofs. These panels can become loose, especially under high wind conditions, leading to leaks and other problems. Leaks in standing seam metal roofs are often caused by improper installation and damage from extreme weather conditions, necessitating careful attention to detail during both installation and maintenance. Failing to accommodate thermal movement properly can also lead to issues such as water infiltration and stress fractures in the seams.

Regular inspections are vital for identifying potential issues before they become major problems. Regular checks help homeowners detect and address problems like fastener failures and open seam laps early, preventing costly repairs and extending the roof’s lifespan.

Addressing Leaks in Standing Seam Metal Roofs

Leaks in standing seam metal roofs typically result from improper installation and weather damage, necessitating careful repair methods. The most common culprits are fastener failures and open seam laps, which can allow water to infiltrate the roof. To combat these issues, it’s essential to seal existing seams and joints, a common restoration technique that can prevent leaks in aging metal roofs.

Addressing leaks effectively involves understanding the specific areas where leaks are likely to occur and using appropriate repair methods. This section will delve into two critical areas: penetration flashing repairs and horizontal seam repairs, each requiring a detailed approach to ensure long-term roof integrity.

Penetration Flashing Repairs

Penetration flashing is a frequent source of leaks in standing seam roofs, primarily due to the expansion and contraction of materials. Preventing leaks involves regularly checking and replacing sealants around penetration points. Ensuring that all sealants are intact and applying new sealants where necessary can maintain a watertight seal and prevent water intrusion.

Maintaining penetration flashing regularly is crucial to preventing leaks. By addressing these points of vulnerability, homeowners can protect their roofs from the damaging effects of moisture and extend the lifespan of their roofing system.

Horizontal Seam Repairs

Horizontal seams in metal roofs can separate over time, creating gaps that allow water intrusion if not properly repaired. Wear and tear can cause these seams to separate, requiring reinforcement and proper sealing to maintain the roof’s integrity against leaks. Using appropriate sealants, like acrylic or urethane, is essential for repairing horizontal seams to ensure they remain waterproof.

Properly sealing horizontal seams involves closing any gaps and ensuring a continuous, watertight barrier. This practice not only prevents leaks but also helps maintain the structural integrity of the roof, ensuring long-term performance and durability.

Fastener Maintenance and Replacement

Fasteners play a critical role in the performance and longevity of a metal roof. The correct installation of roofing screws is vital, as driving screws too deep or at the wrong angle can lead to leaks. Inspecting and maintaining exposed fasteners regularly prevents water penetration and ensures the roof’s durability.

Choosing a wider size than the original is essential when replacing fasteners to ensure proper threading in existing holes. This step ensures a secure fit and prevents future issues related to loose fasteners, thereby maintaining the roof’s integrity and performance.

Handling Metal Roof Oxidation

Oxidation occurs when metal surfaces, particularly fasteners, are exposed to moisture, causing corrosion that weakens the materials. This can greatly impact the durability of a metal roof, necessitating proactive handling of oxidation. Using high-quality metal panels that contain zinc can prevent rusting and protect cut edges. Additionally, applying a fresh coat of paint or primer with high zinc content can significantly enhance a metal roof’s resistance to rust.

Elastomeric, silicone, or acrylic coatings form a protective barrier against corrosion on metal roofs. Opting for fasteners with high corrosion resistance is crucial, as rust on screws can result from moisture exposure. Rust should be removed promptly to prevent further damage and corrosion.

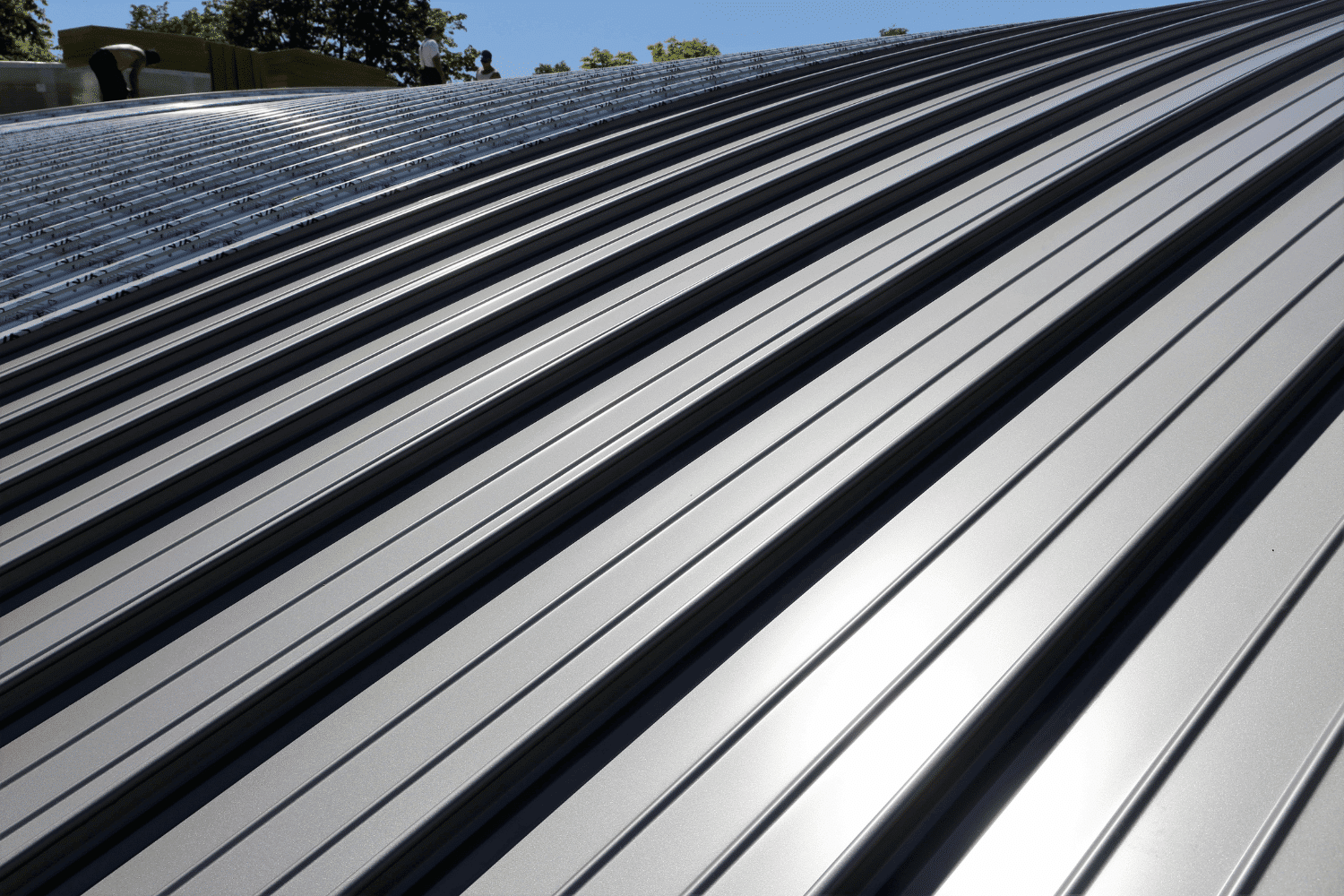

The Role of Thermal Movement in Standing Seam Roofs

Standing seam roofs are specifically designed to allow for thermal movement, which accommodates expansion and contraction due to temperature changes. Temperature fluctuations cause standing seam roofs to expand and contract significantly; for instance, aluminum can expand over 0.3 inches in a 10-foot section with a 200°F temperature change.

The design includes clips that let the new panel move freely, allowing thermal movement without causing damage. Fixed points in the installation prevent excessive panel sliding, directing thermal movement away from the fasteners.

Understanding and accommodating thermal expansion prevents stress fractures and other issues that could compromise the roof’s integrity.

Choosing Between Repair, Restoration, and Replacement

When faced with issues in standing seam metal roofs, homeowners must decide between repair, restoration, and complete replacement. Metal roofs can often be restored multiple times if structurally sound, offering considerable savings over full replacement. Assessing the roof’s condition is crucial to determine the most suitable option.

This section will explore the three primary approaches: repair and maintain, restoration techniques, and complete replacement. Each option has its own set of benefits and considerations, and understanding these can help homeowners make the right choice for their specific situation.

Repair and Maintain

Regular inspections and minor repairs can significantly extend the life of a standing seam metal roof. Annual maintenance helps spot potential problems early, preventing more extensive damage. Addressing minor issues promptly preserves the roof’s integrity and avoids costly repairs.

Evaluating the roof’s condition determines whether repair or replacement is necessary based on the damage extent. For residential and commercial applications, timely minor repairs and consistent maintenance are cost-effective ways to protect the roofing investment.

Restoration Techniques

Re-coating and sealing can rejuvenate aging roofs, extending their lifespan. Roof re-coating involves applying a new protective layer over the existing surface, improving aesthetics and performance. Sealing techniques prevent moisture infiltration and significantly reduce the risk of leaks and other roof issues.

Implementing restoration techniques can lead to significant cooling costs savings by delaying the need for complete roof replacement. Using reflective roof coatings enhances energy efficiency and extends the roof’s lifespan.

Complete Replacement

Complete roof replacement may be necessary if repairs exceed 10% of the roofing area or if structural integrity is compromised. Extensive rust or structural damage often indicates that a complete metal roof replacement is necessary. Installing a new standing seam metal roof can greatly enhance the longevity and performance of the roofing system.

A new roof installation can improve energy efficiency and aesthetics, adding value to the property. While replacement is more costly, it can be the right choice when repairs and restoration no longer effectively address the roof’s deterioration.

Professional vs. DIY Standing Seam Roof Repair

Safety hazards are significantly higher in DIY installations, especially for those lacking experience in using tools and working at heights. DIY installations may also lead to higher long-term maintenance costs due to the risk of improper installation. Considering professional help for standing seam roof repairs can lead to a safer, more effective outcome.

Hiring a professional contractor ensures proper installation and reduces long-term maintenance issues. Balancing cost-efficiency with safety and expertise is crucial when deciding between professional contractors and DIY roof repairs.

Preventative Measures for Long-Lasting Standing Seam Roofs

Regular maintenance checks detect early signs of seam separation, ensuring timely repairs and preventing extensive damage. Screws should be inspected regularly to check for movement and sealant failures, as these can lead to water penetration. Structural maintenance on a metal roof at least once every two years is recommended.

Cleaning gutters and drains prevents water pooling, which can lead to corrosion on metal roofs. Clearing debris like leaves and branches from the roof prevents moisture buildup and corrosion. Regular cleaning helps identify rust early and prevents its spread, ensuring the roof’s longevity.

Summary

Maintaining a standing seam metal roof involves understanding common issues, implementing effective repair techniques, and deciding between repair, restoration, and replacement. Regular inspections and preventative measures can significantly extend the life of these durable and aesthetically pleasing roofs.

By choosing the right approach—whether it’s timely repairs, restoration, or complete replacement—homeowners can ensure their standing seam metal roofs provide long-lasting protection and enhance the value of their properties. Remember, the key to a long-lasting roof lies in proactive care and informed decision-making.

Frequently Asked Questions

What are the common issues with standing seam metal roofs?

Standing seam metal roofs can face issues like poorly secured panels, leaks from improper installation, and problems with thermal movement and fasteners. It’s essential to ensure proper installation to avoid these troubles.

How often should I inspect my standing seam metal roof?

You should inspect your standing seam metal roof at least twice a year to catch any issues early and avoid expensive repairs. This regular check-up helps keep your roof in great shape!

What are the benefits of restoring a metal roof instead of replacing it?

Restoring a metal roof can save you money while extending its lifespan and boosting energy efficiency. Plus, it gives your home a fresh look without the hassle of a full replacement.

Is it safe to perform DIY repairs on a standing seam metal roof?

It’s best to skip the DIY repairs on a standing seam metal roof, as it can be risky and result in costly mistakes. Hiring a professional ensures safety and proper installation, keeping your roof in great shape.

What preventative measures can extend the life of a standing seam metal roof?

To extend the life of your standing seam metal roof, make sure to regularly perform maintenance checks, clean gutters and drains, and clear any debris. These simple steps can prevent extensive damage and keep your roof in great shape.

Residential Roofing

Residential Roofing Storm Damage

Storm Damage Multi-Family Homes

Multi-Family Homes