The Best Practices for Sheathing for Metal Roof Installation

Choosing the right sheathing for a metal roof is crucial for a stable and long-lasting installation. This guide will explain why sheathing matters, explore different materials, and provide step-by-step installation tips. By the end, you’ll be equipped to make informed decisions about your metal roof sheathing.

Key Takeaways

-

Sheathing is essential for the stability, durability, and energy efficiency of metal roofs, serving as a protective barrier against moisture and environmental stressors.

-

Choosing between plywood and OSB for sheathing requires consideration of factors like moisture resistance, cost, and environmental impact, as both materials have distinct advantages.

-

Proper preparation, installation practices, and the use of moisture barriers can significantly enhance the longevity and performance of a metal roofing system, while avoiding common mistakes is crucial for maintaining its structural integrity.

Importance of Sheathing for Metal Roofs

Sheathing serves as the backbone of a metal roof installation. Acting as a substrate, it provides a secure base for attaching metal panels, which prevents movement and potential damage. This foundational role is critical in ensuring the stability and integrity of the entire roofing system.

Additionally, sheathing plays a significant role in extending the lifespan of the roofing system by minimizing the risk of water infiltration. This barrier against moisture helps prevent issues like rot and mold, preserving the structural integrity of the roof. This added layer of protection enhances the overall durability of the roof, making it better equipped to withstand harsh weather conditions.

Moreover, proper sheathing installation helps in maintaining consistent roof temperature and reducing energy costs. It provides an extra layer of insulation that helps regulate indoor temperatures, contributing to a more energy-efficient home. This not only makes your living space more comfortable but also contributes to long-term savings on energy bills.

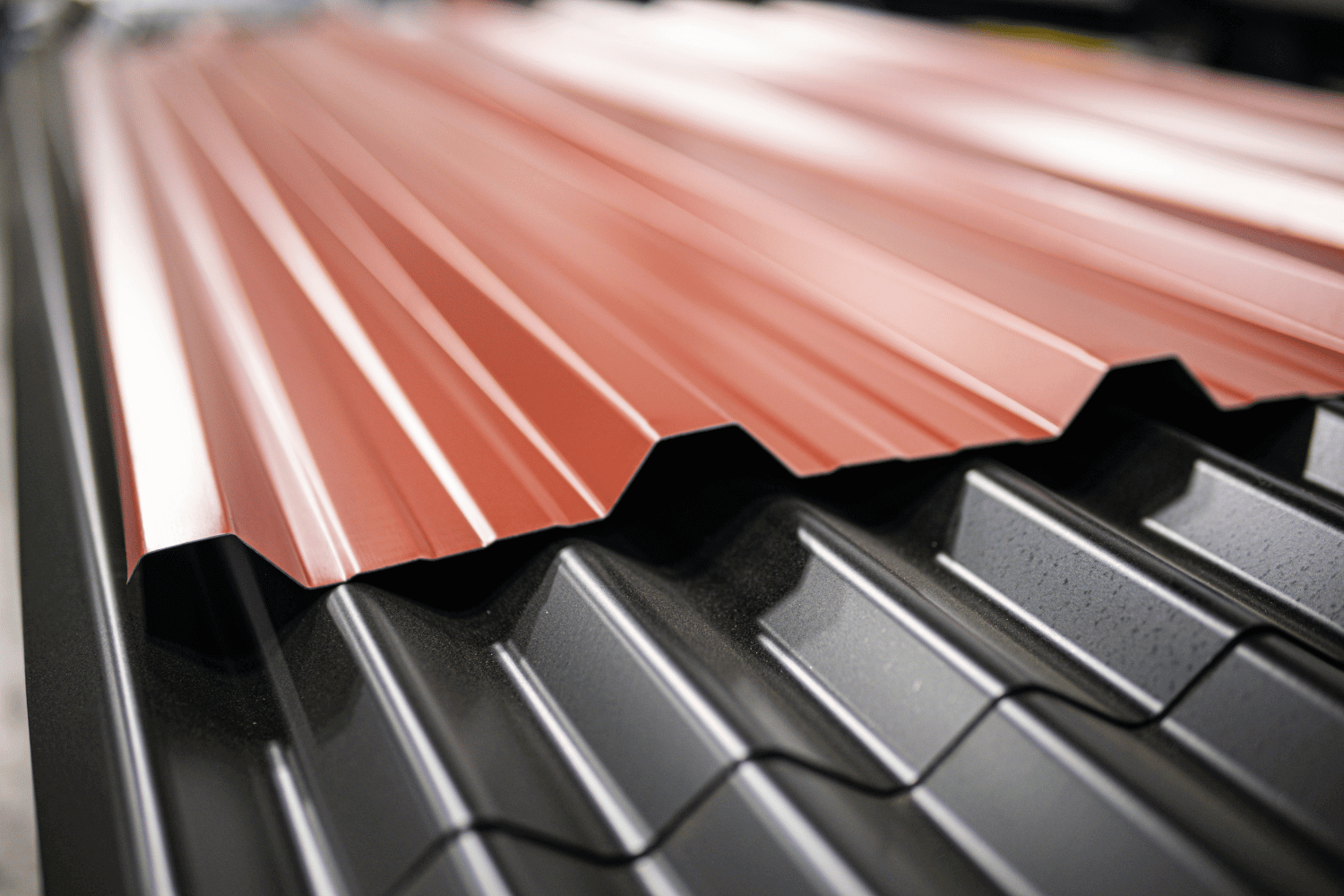

Types of Sheathing Materials for Metal Roofing

Selecting the right sheathing material is paramount to the success of your metal roof installation. Plywood is a popular choice due to its strength and moisture resistance. Created by cross-laminating wood veneers, plywood boasts enhanced strength through a process called cross-graining. Its ability to dry quickly and resist swelling makes it a reliable option, although it is vulnerable to delamination in humid environments.

On the other hand, Oriented Strand Board (OSB) is another commonly used material. Made from wood strands bonded together with resin and subjected to heat and pressure, OSB tends to be more affordable than plywood, often costing about $4 less per 4×8 sheet. OSB is also considered more environmentally friendly because it uses smaller trees and maximizes wood utilization.

Choosing between plywood and OSB involves considering factors like cost, environmental impact, and specific project requirements. While plywood generally offers better moisture resistance and stiffness, OSB’s affordability and sustainability can make it an attractive alternative.

Preparing Your Roof for Sheathing

Preparation is key to a successful sheathing installation. Begin by thoroughly inspecting the roof structure to identify any damaged or rotten plywood. Replace any areas showing signs of rot or water damage to ensure a solid foundation for the new sheathing.

Next, ensure that the roof surface is smooth, dry, and free from any debris or obstacles. This step is vital for the proper adherence of the sheathing and to prevent any issues during the installation of the metal panels. Removing old shingles is also necessary to expose an even surface for the new sheathing.

Taking these preparatory steps will help create a clean and stable base, ensuring that the sheathing installation goes smoothly and that the metal roof has a strong and durable foundation.

Installing Plywood Sheathing

Installing plywood sheathing requires attention to detail and adherence to best practices. Begin by ensuring the plywood is clean of dirt and dust before installation. Starting at the bottom left side of your roof, lay the plywood flush, ensuring it is properly aligned and secured.

Check for adequate adherence at the eaves and uniformity of shape before proceeding to the next sheet. This step is crucial for maintaining the structural integrity of the roof and preventing any gaps or misalignments that could compromise the installation.

Ensure the plywood complies with the American Plywood Association or Department of Commerce standards to guarantee its quality and suitability for the project. Finally, when installing the metal panels, make sure they overlap by one inch at the edges to create a seamless and secure roofing over plywood system.

These detailed steps will help achieve a robust and reliable roof sheathing that effectively supports the entire metal roofing systems.

Benefits of Using Plywood Sheathing

Using plywood sheathing offers numerous benefits that enhance the overall performance and longevity of your metal roof. One of the primary metal roof advantages is its ability to act as a protective barrier against storms and debris, significantly enhancing the roof’s resilience.

Plywood sheathing also improves the structural integrity of the roof, making it more durable over time. This added strength ensures that the roofing system can withstand environmental stressors and maintain its performance for years to come.

Installing plywood sheathing can also be a cost-effective decision. It reduces the potential for costly repairs down the line, leading to long-term savings. This proactive approach helps minimize future structural repair costs associated with roof damage, making it a financially wise investment.

Underlayment for Metal Roofs over Sheathing

Underlayment serves as the final protective layer for the roof deck, guarding against moisture intrusion and extending the life of the roofing underlayment system. Neglecting to use an appropriate underlayment can result in severe moisture issues and damage to the roof structure.

There are various types of underlayments available, including felt, asphalt, and synthetic options. Synthetic underlayments, in particular, outperform traditional felt in terms of durability, tear resistance, and overall performance. Self-adhered underlayments offer a waterproof seal, making them highly effective at preventing ice dams and water intrusion.

Selecting the right metal roofing underlayment requires consideration of local climate, building codes, and roofing professionals’ recommendations. High temperatures generated by metal roofs require underlayment that can withstand these conditions. Additionally, synthetic underlayments often feature non-skid surfaces, improving safety during installation and ensuring accurate fastener placement.

For proper installation, ensure that all plywood is covered without gaps. This comprehensive approach to underlayment selection and installation will significantly enhance the performance and durability of your metal roofing system.

Moisture Barriers and Slip Sheets

Moisture barriers and slip sheets are additional protective measures that further enhance the durability of your metal roofing material system. A moisture barrier or slip sheet serves as an extra layer of protection, preventing moisture damage and prolonging the life of the roof.

Slip sheets are particularly useful in protecting the underlayment from tearing due to the expansion and contraction of the metal roof. They facilitate drainage, allowing any trapped moisture to escape and reducing the risk of rot.

These sheets are designed specifically for metal roofs and metal roof panels are made of reinforced polypropylene, providing effective moisture control and enhancing the roof’s overall performance. Incorporating these additional layers into your roofing system ensures that it remains robust and resistant to environmental stressors.

Common Mistakes to Avoid When Sheathing for Metal Roofs

Avoiding common mistakes during sheathing installation is crucial to ensure the integrity and longevity of your metal roof. One of the most frequent errors is failing to properly align sheathing panels, which can lead to gaps that compromise the roof’s structural integrity.

Using inadequate fasteners or not following the manufacturer’s recommendations for fastener spacing can weaken the roof and lead to potential failures. DIY installations, if not performed to professional standards, can result in higher maintenance costs and earlier repairs.

Additionally, not accounting for thermal expansion can cause buckling and warping of the metal panels, further reducing the roof’s effectiveness. By being aware of these common pitfalls and taking steps to avoid them, you can ensure a successful and durable sheathing installation.

Safety Tips During Sheathing Installation

Safety should always be a top priority when installing sheathing for a metal roof. Securing oneself while on the roof is essential due to the risk of slipping and falling. Avoid working on the roof during wet or windy conditions to further reduce slip risks.

Always ensure that ladders are stable and set on a flat surface before ascending. Wearing cut-resistant gloves can safeguard your hands when handling metal sheets, while safety harnesses are crucial, especially on steep roofs, to prevent falls. Additionally, wearing safety goggles will protect your eyes from debris while cutting metal.

Keeping tools organized and away from roof edges can prevent accidental falls and ensure a safer working environment. These rubber pipe boot kits help reduce hazards and ensure a smooth installation process.

Professional vs. DIY Sheathing Installation

When deciding between professional and DIY sheathing installation, several factors come into play. Professional contractors often have access to wholesale materials, which can make overall costs lower than DIY if you factor in retail prices. Their expertise and experience ensure that the installation is performed to the highest standards, reducing the risk of errors and future repairs.

If you have confidence in your handiwork skills and the necessary tools, you can install metal roofs without professional help. However, it’s essential to weigh the potential risks and benefits carefully. Professional installations typically come with warranties on both materials and labor, offering long-term protection against defects.

The choice between professional and DIY installation ultimately depends on your skill level, budget, and project complexity. Consider these factors carefully to make an informed decision that best suits your needs.

Rapid Roofing’s Sheathing Services

Rapid Roofing specializes in roof sheathing, offering high-quality materials such as plywood and OSB to ensure a durable and uniform base for your roofing materials. Their expertise in structural support and leak prevention has made them a trusted choice for homeowners looking to enhance the integrity of their roofs.

Professional installation services from Rapid Roofing typically include warranties on both materials and labor, providing long-term protection against defects and peace of mind for customers. They emphasize the importance of regular inspections and maintenance to extend the lifespan of the roof sheathing, ensuring that any potential issues are addressed promptly.

Customer satisfaction is at the core of Rapid Roofing’s mission. They focus on delivering high-quality workmanship and adhering to local building codes, ensuring that every project meets the highest standards of safety and durability. If you’re considering a new metal roof or aluminum roofing, Rapid Roofing’s sheathing services are designed to provide a solid foundation for your investment in steel roofing and metal roofing directly.

Signs You Need New Sheathing

Identifying the signs that you need new sheathing is crucial to maintaining the integrity of your roofing system. Visible signs of damage, such as sagging or warping, are clear indicators that the sheathing may require replacement. These issues can compromise the structural stability of the roof and should be addressed promptly.

Leaks and rot are other key indicators that your roof sheathing might need to be replaced. Moisture infiltration can lead to significant damage over time, affecting both the sheathing and the overall roofing structure. Recognizing these signs early can prevent further damage and costly repairs.

Timely replacement of damaged sheathing is essential to maintain the roofing structure and protect interior spaces from water damage. Staying vigilant and addressing these signs promptly helps ensure the longevity and performance of your metal roof.

Summary

Proper sheathing is a critical component of a successful metal roof installation. It provides a secure base for metal panels, enhances the roof’s durability, and helps maintain consistent temperatures, leading to energy savings. Selecting the right sheathing material, such as plywood or OSB, and ensuring meticulous preparation and installation can significantly impact the roof’s performance and longevity.

Whether you choose to undertake the installation yourself or hire professionals like Rapid Roofing, understanding the importance of sheathing and following best practices will help you achieve a resilient and efficient roofing system. By prioritizing these steps, you can enjoy the many benefits of a well-installed metal roof for years to come.

Frequently Asked Questions

Why is sheathing important for metal roofs?

Sheathing is crucial for metal roofs as it offers a stable foundation for the panels, reduces movement, and lowers the risk of water infiltration, thereby increasing the roof’s durability and lifespan.

What materials are commonly used for roof sheathing?

Plywood and oriented strand board (OSB) are the most commonly used materials for roof sheathing. Plywood provides superior moisture resistance and stiffness, whereas OSB is a cost-effective and environmentally friendly option.

How do I prepare my roof for sheathing installation?

To prepare your roof for sheathing installation, inspect and replace any damaged plywood, ensure the surface is smooth and dry, and remove old shingles for an even base. This will promote a proper installation and enhance durability.

What safety measures should I take during sheathing installation?

During sheathing installation, it is essential to use a safety harness, avoid working in adverse weather conditions, ensure ladder stability, and wear appropriate safety gear like cut-resistant gloves and safety goggles. Additionally, maintaining an organized workspace with tools will enhance safety.

How can I tell if I need new sheathing?

If you observe visible damage such as sagging, warping, or signs of leaks and rot, it is indicative that you may need new sheathing. Timely replacement is essential to prevent additional complications.

Residential Roofing

Residential Roofing Storm Damage

Storm Damage Multi-Family Homes

Multi-Family Homes